.

Workflow for Simple, Fast, Low Cost & High-Throughput EzPrep123 Dioxin/PCB sample CleanUp

SemiAutomated EzPrep Dioxin CleanUp Automated EzPrep+ Dioxin CleanUp Automated EconoPrep Dioxin CleanUp Automated PowerPrep Dioxin CleanUp

EzPrep123

Semi-Automated Sample Clean-Up For Dioxin, PCB & PBDE Analysis

Semi-Automated EzPrep 123™ Dioxin Sample Clean-Up

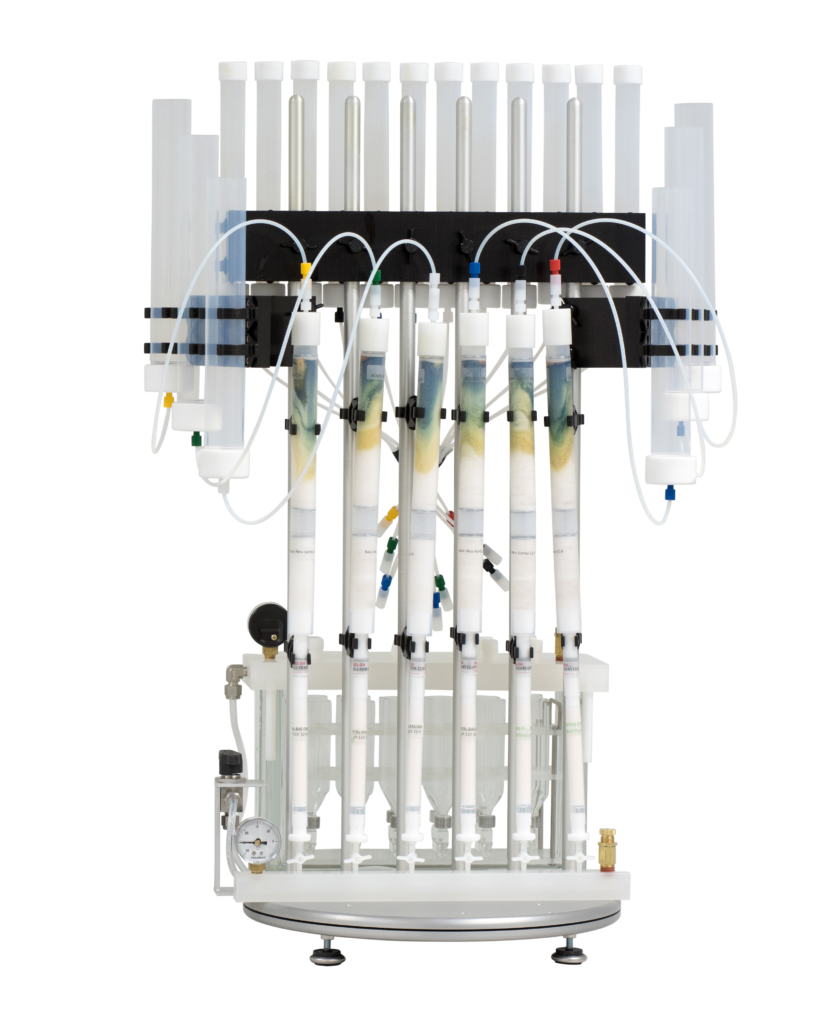

The EzPrep 123™ is a semi-automated solution for Dioxin sample clean-up and PCB analysis, designed to deliver rapid, accurate, and reproducible results. This innovative system simplifies complex workflows, enabling high analyte recoveries in under 30 minutes. Whether you’re processing environmental or food samples, the EzPrep 123 streamlines your laboratory operations for maximum efficiency.

User-Friendly Operation

First and foremost, the EzPrep 123™ is engineered for ease of use. With a simple rotary workstation, users can complete Dioxin and PCB sample clean-up in just three steps: fill the solvent reservoir, install the cleanup column, and start the process. Additionally, the system operates without complex electronics or moving parts, minimizing maintenance and maximizing uptime.

Green Technology

Importantly, the EzPrep 123 eliminates the use of dichloromethane (DCM), making it a greener alternative to traditional Dioxin sample preparation methods. As a result, labs benefit from reduced solvent use, lower disposal costs, and a safer working environment.

High Throughput in a Compact Footprint

The system processes up to six samples simultaneously. Thanks to its compact design, multiple units can run side-by-side in a single fume hood—allowing for the daily processing of hundreds of samples. This makes the EzPrep 123 ideal for high-throughput laboratories performing Dioxin and PCB analysis.

Versatile Applications

The EzPrep 123 supports a wide range of matrices. It’s suitable for solids like fish, meat, animal feed, soil, and fly ash, as well as liquids such as milk, oil, serum, water, and wastewater. This versatility ensures reliable Dioxin and PCB results across diverse sample types.

Experience the reliability and performance of the EzPrep 123™—where simplicity meets smart, semi-automated Dioxin sample clean-up.

📄 Learn more about standard methods for Dioxin and PCB analysis:

Key Features:

-

Simplicity: The system operates with a straightforward three-step process, making it user-friendly and easy to run.

-

Speed: Capable of processing samples in 30 to 45 minutes, the EzPrep+ ensures rapid turnaround times.

-

Environmental Friendliness: Utilizing green technology, the system operates without the use of dichloromethane (DCM), reducing environmental impact.

-

Safety: As a closed system, it minimizes exposure to harmful chemicals, enhancing laboratory safety.

-

High Throughput: The EzPrep+ can process between 1 to 6 samples in parallel, increasing laboratory efficiency.

-

Low Solvent Usage: It requires as little as 110 ml of solvent per sample, promoting cost-effectiveness and environmental responsibility.

-

Reliability: Designed with no computers or electromechanical valves, the system minimizes downtime and maintenance needs.

-

High Fat Capacity: The system can handle up to 5 grams of fat, with options for up to 7 grams for special orders, making it versatile for various sample types.

-

Quality Consumables: It uses guaranteed certified columns, ensuring consistent and reliable results.

-

Economical: The EzPrep+ offers column kits tailored to meet specific sample matrices, providing cost-effective solutions for diverse laboratory needs

Benefits

- Time-Saving: Accelerates sample preparation, enabling labs to process more samples in less time.

- Cost-Effective: Reduces labor costs and consumable usage with its streamlined operation.

- Reliable Results: Delivers consistent Sample Clean-Up efficiency, ensuring reproducible results across multiple runs.

- Ease of Use: Intuitive interface and minimal training requirements make it accessible to all users.