From herbs to oils, extract more in less time using precision-engineered

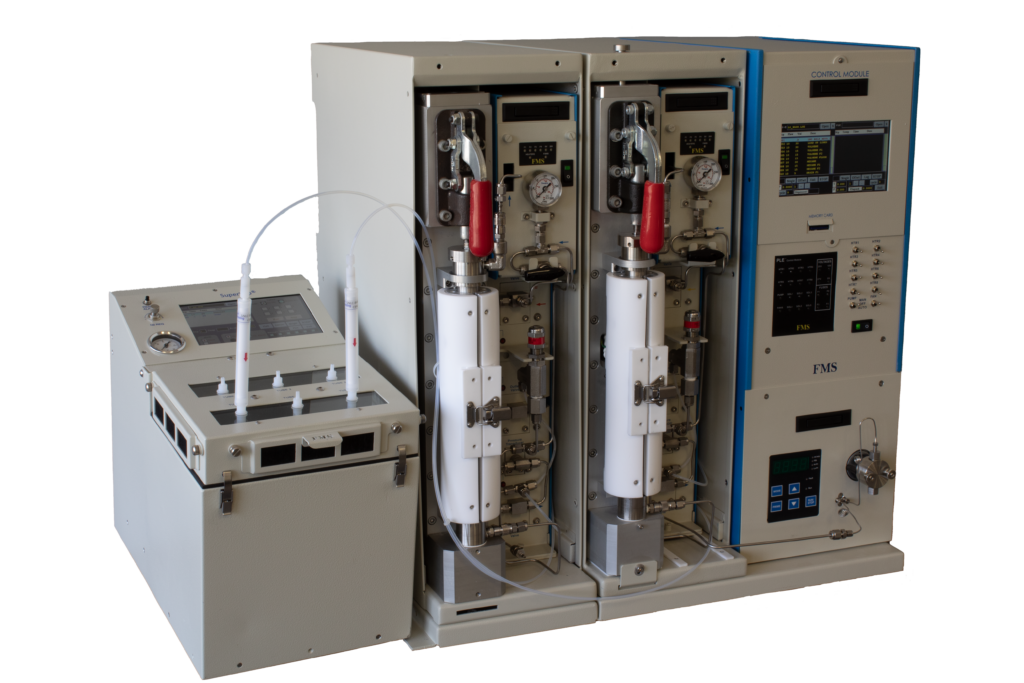

PLE - Pressurized Liquid Extraction

Automated Extraction of Natural Products

Brochure | Application Notes | Video

Key Features:

-

Broad Solvent Compatibility: Use ethanol, methanol, water, or custom mixtures with one validated method.

-

Fully Automated Operation: Touch-screen control and real-time data logging for pressure/temperature.

-

Integrated Cleanup & Concentration: Direct transfer to SuperVap for one-step extract-to-oil processing.

-

Scalable & Modular Design: Expand from 1 to 8 extractors—process 4 to 32 lbs. in an 8-hour shift.

-

Flexible Cell Sizes: Use the same unit for 5 mL to 200 mL stainless steel extraction cells with reusable filters.

-

Energy-Efficient & Green: Uses 2/3 less solvent than traditional methods, and lower energy than CO₂ systems.

-

Superior for Polar Compounds: Excels where SFE struggles—extracts phenolics, terpenes, and phytochemicals with ease.

-

Compact & Mobile: Operates on a 110V & 220V ; footprint fits on benchtops or portable carts.

-

Low Operating Costs: Reduced solvent, labor, and waste disposal lead to long-term savings.

-

Enhanced Safety Features: Built-in overpressure protection, automatic shutdown, and remote monitoring ensure safe, uninterrupted operation.

Advanced Plant Extraction for Natural Products

Plant extraction is essential in producing high-quality natural products, and FMS delivers a modern, automated solution built for speed, efficiency, and sustainability. Our systems are designed to extract bioactive compounds—such as antioxidants, terpenes, carotenoids, and phenolics—from plant-based sources using high temperature and pressure. Compared to traditional methods like Soxhlet extraction, our process is significantly faster, more efficient, and uses less solvent.

This advanced system supports a wide range of solvents and integrates easily with automated cleanup and concentration tools. Whether you’re in nutraceuticals, cosmetics, pharmaceuticals, or botanical research, FMS offers a scalable, high-performance platform for extracting natural compounds at every stage—from lab-scale to full production.

Green & Cost-Effective Operation

Our systems dramatically reduce solvent use—cutting consumption by two-thirds compared to traditional methods. Additionally, PLE consumes far less power than CO₂ or butane systems, helping you lower your environmental impact and reduce operational costs without compromising performance.

Versatile Cell Sizes for All Sample Volumes

FMS PLE systems accommodate stainless steel extraction cells ranging from 5 mL to 200 mL. The same unit can process different cell sizes in a single run, maximizing flexibility for various natural product sources such as roots, leaves, seeds, or powders.

Compact, Plug-and-Play Design

Designed for versatility and convenience, all PLE models run on a standard 110V 20A outlet and fit on countertops or portable carts. Whether you’re in a research lab or a small-scale production facility, the compact footprint and ease of setup make deployment simple and cost-effective.

Fast, High-Yield Extraction in Minutes

FMS PLE systems deliver rapid, high-efficiency extraction of natural products using elevated temperature and pressure. What traditionally takes hours or days can now be done in as little as 10 minutes. Our systems yield up to 30% and recover over 90% of targeted compounds—ideal for high-demand industries like nutraceuticals, cosmetics, and herbal oils.

Solvent Flexibility for All Natural Matrices

Our pressurized liquid extraction platform supports a wide range of solvents including ethanol, methanol, water, and custom solvent blends. Whether you’re extracting polar phenolics or non-polar terpenes, PLE enables a single validated method to cover all compound classes—no need to develop multiple protocols.

Fully Automated Workflow with Real-Time Monitoring

Each PLE system comes equipped with a user-friendly touchscreen interface and real-time temperature/pressure plotting. Eight pressure channels can be monitored and documented simultaneously. This automation minimizes operator input while ensuring consistent, reproducible results every time.

One-Step Extraction, Cleanup & Concentration

The FMS PLE platform simplifies workflows by integrating supercooled ethanol cleanup and optional direct transfer to the SuperVap® concentrator. This one-step system eliminates manual handling and reduces cleanup steps—delivering ready-to-use, purified oils or concentrates with minimal labor.

Modular, Scalable System – From R&D to Production

Start small and grow as your operation expands. FMS offers scalable configurations from 1 to 8 modules. Each unit processes up to 4 lbs. of material per hour (32 lbs. in 8 hours for 8 modules). Ideal for everything from benchtop research to full-scale production.

From herbs to oils, extract more in less time using precision-engineered

PLE systems built for performance and growth

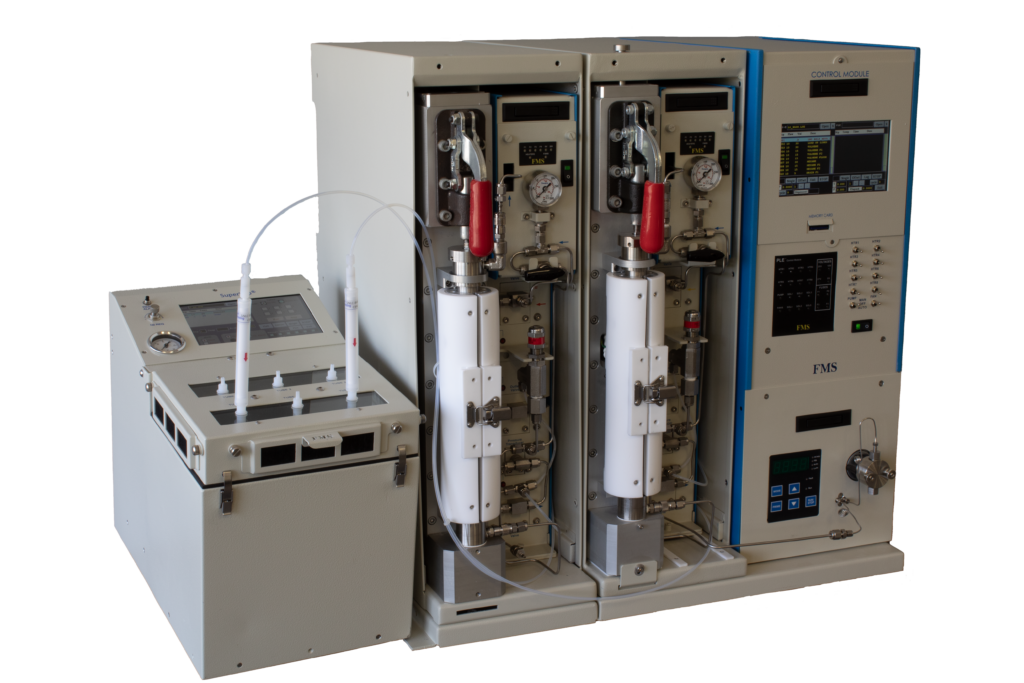

PLE - Pressurized Liquid Extraction

Automated Extraction of Natural Products

Brochure | Application Notes | Video

Advanced Plant Extraction for Natural Products

Plant extraction is essential in producing high-quality natural products, and FMS delivers a modern, automated solution built for speed, efficiency, and sustainability. Our systems are designed to extract bioactive compounds—such as antioxidants, terpenes, carotenoids, and phenolics—from plant-based sources using high temperature and pressure. Compared to traditional methods like Soxhlet extraction, our process is significantly faster, more efficient, and uses less solvent.

This advanced system supports a wide range of solvents and integrates easily with automated cleanup and concentration tools. Whether you’re in nutraceuticals, cosmetics, pharmaceuticals, or botanical research, FMS offers a scalable, high-performance platform for extracting natural compounds at every stage—from lab-scale to full production.

Fast, High-Yield Extraction in Minutes

FMS PLE systems deliver rapid, high-efficiency extraction of natural products using elevated temperature and pressure. What traditionally takes hours or days can now be done in as little as 10 minutes. Our systems yield up to 30% and recover over 90% of targeted compounds—ideal for high-demand industries like nutraceuticals, cosmetics, and herbal oils.

Solvent Flexibility for All Natural Matrices

Our pressurized liquid extraction platform supports a wide range of solvents including ethanol, methanol, water, and custom solvent blends. Whether you’re extracting polar phenolics or non-polar terpenes, PLE enables a single validated method to cover all compound classes—no need to develop multiple protocols.

Fully Automated Workflow with Real-Time Monitoring

Each PLE system comes equipped with a user-friendly touchscreen interface and real-time temperature/pressure plotting. Eight pressure channels can be monitored and documented simultaneously. This automation minimizes operator input while ensuring consistent, reproducible results every time.

One-Step Extraction, Cleanup & Concentration

The FMS PLE platform simplifies workflows by integrating supercooled ethanol cleanup and optional direct transfer to the SuperVap® concentrator. This one-step system eliminates manual handling and reduces cleanup steps—delivering ready-to-use, purified oils or concentrates with minimal labor.

Modular, Scalable System – From R&D to Production

Start small and grow as your operation expands. FMS offers scalable configurations from 1 to 8 modules. Each unit processes up to 4 lbs. of material per hour (32 lbs. in 8 hours for 8 modules). Ideal for everything from benchtop research to full-scale production.

Key Features:

-

Broad Solvent Compatibility: Use ethanol, methanol, water, or custom mixtures with one validated method.

-

Fully Automated Operation: Touch-screen control and real-time data logging for pressure/temperature.

-

Integrated Cleanup & Concentration: Direct transfer to SuperVap for one-step extract-to-oil processing.

-

Scalable & Modular Design: Expand from 1 to 8 extractors—process 4 to 32 lbs. in an 8-hour shift.

-

Flexible Cell Sizes: Use the same unit for 5 mL to 200 mL stainless steel extraction cells with reusable filters.

-

Energy-Efficient & Green: Uses 2/3 less solvent than traditional methods, and lower energy than CO₂ systems.

-

Superior for Polar Compounds: Excels where SFE struggles—extracts phenolics, terpenes, and phytochemicals with ease.

-

Compact & Mobile: Operates on a 110V & 220V ; footprint fits on benchtops or portable carts.

-

Low Operating Costs: Reduced solvent, labor, and waste disposal lead to long-term savings.

-

Enhanced Safety Features: Built-in overpressure protection, automatic shutdown, and remote monitoring ensure safe, uninterrupted operation.

Green & Cost-Effective Operation

Our systems dramatically reduce solvent use—cutting consumption by two-thirds compared to traditional methods. Additionally, PLE consumes far less power than CO₂ or butane systems, helping you lower your environmental impact and reduce operational costs without compromising performance.

Versatile Cell Sizes for All Sample Volumes

FMS PLE systems accommodate stainless steel extraction cells ranging from 5 mL to 200 mL. The same unit can process different cell sizes in a single run, maximizing flexibility for various natural product sources such as roots, leaves, seeds, or powders.

Compact, Plug-and-Play Design

Designed for versatility and convenience, all PLE models run on a standard 110V 20A outlet and fit on countertops or portable carts. Whether you’re in a research lab or a small-scale production facility, the compact footprint and ease of setup make deployment simple and cost-effective.